Categories

Style FW Flange Steel Plate

Size: DN50~DN200 2"~8"

key word::

Category:

- Description details

-

Products Presentation

Three traditional methods to connect steel pipes, namely welding, flange connection and screwconnection.

Grooved piping system use the grooved couplings & branch outlet fittings as the key,supplemented by a variety of non-gasket pipefittings, This is a pipe connection revolution. Atpresent, CNG manufactures all kinds of grooved branch outlet fittings and non-gasket fittings. Inorder to meet the needs of customers, CNG also developed extended products such as groovedend valves, filters, etc. CNG will continue to improve and optimize so that the company'sproduct line can fulfill demands in civil construction, municipal and industrial fields..

Groove piping system is an universal, economic, safe and practical piping systemcomponents, the installation process will not bring any pollution to the pipeline. lt is an

environmentally friendly green product.Groove piping system builds pipe connection on the external surface of steel pipes. Theinner diameter & interior surface of the pipe has no matter of the connection, which makes therange of application of this product much more extended.

Products Strong Point

Compared with the traditional piping methods such as welded, flanges or threaded connection,the grooved and mechanical outlet fittings has very significant advantages, mainly in thefollowing aspects:

◆ Rigid

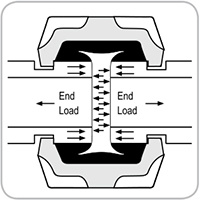

⊙ Rigid coupling providesenough rigidity to resisttube twisting and bendingmoment.

◆ Noise and vibration

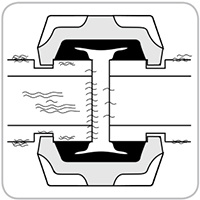

⊙The separation betweenpipe ends reduces thetransmission of noise andvibration,provides theentire system a significant dampening effect.

◆ system maintenance

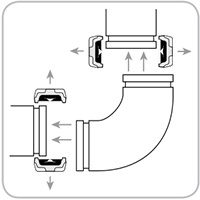

⊙System unit can bedisassembled without movingthe pipeline, thus facilitatingsystem maintenance and modification.

◆ Flexibility

⊙ Flexible coupling providesradial and axial deflection.It absorbs expansion,contraction,deflection andvibration.

◆ Earthquake stress

⊙ The full circumferential engage between couplings keys and pipe groovesprovides sufficient internal pressure and pipe end load capacity to withstand pipe movement.

◆ Easy alignment

⊙ Groove system allows free rotation of pipe and system components prior final fixing.

Warning

Before attempting to install, disassemble, and adjust any CNG product,please depressurize anddrain the plumbing system. Failure to do this may result in personal injury, property damage, leaksand/or other potential function failure.

Products Component

● Housing

Material:Ductile cast iron conforming to ASTM A-536, Grade 65-45-12.

Surface Finish:Standard:Epoxy powder coating

Optional:Galvanized (Zinc Plated、HDG), Dip painted

Surface Color:Variable colors for choice

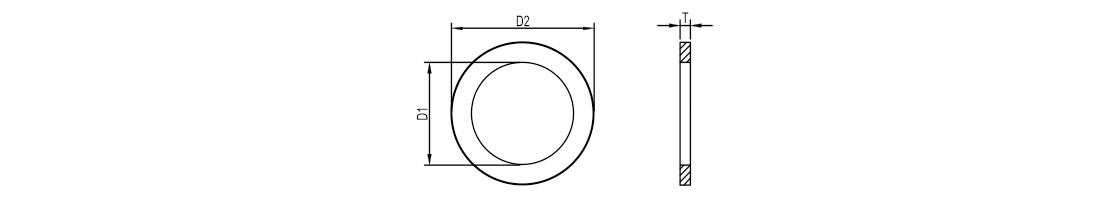

● Rubber Gasket

Standard: EPDM.

Optional:Nitrile, Silicone, Fluoroelastomer, Neoprene

The sealing mechanism of grooved couplings and mechanical outlets is basically the same,the main structure of the gasket has "C" shape, forming a triple seal function. The first seal is formed by the elasticity of the gasket during the static state. After the coupling is installed,the gasket is confined by the housing of groove coupling or the mechanical outlet, the second seal is formed. Medium inside the pipe system press the "C" cavity after pressurizing, it increases the adhesion between gasket lip and steel pipe surface, so as to achieve the third reactive seal. The greater the pressure of the fluid within the pipe, The better the sealing of the coupling.

The material of the gasket must be chosen to follow the characteristics of the fluid medium below. The commonly used gasket are shown in the following table:

Grade Temperature Range Rubber Compound Color Code General Service Recommendations E -30°F to +230°F -34℃ to+110℃ EPDM Green Stripe Recommended for hot water service within the specified temperature range plus a va- riety of dilute acids,oil-free air and many chemical services.UL classified in accordance with ANSI/NSF 61 for cold +86°F/+30℃ and hot+180°F/+82℃ potable water service.

NOT RECOMMENDED FOR PETROLEUM SERVICES.T -20°F to+180°F -29C to+82℃ Nitrile Orange Stripe Recommended for petroleum products,hydrocarbons,air with oil vapors,vegeta-

ble and mineral oils within the specified temperature range;except hot dry air over +140°F/+60℃ and water over +150°F/+66℃.

NOT RECOMMENDED FOR HOT WATER SERVICES.0 -20°F to+300°F -29℃ to+149℃ Fluoroelastomer Blue Stripe Recommended for many oxidizing acids,petroleum oils,halogenated hydrocarbons,lu- bricants,hydraulic fluids,organic liquids and air with hydrocarbons to +300°F/+149℃. L -30°F to+350F -34C to+177C Silicone Body white Recommended for dry heat,air without hydrocarbons to +350°F/+177℃ and certain chemical services. V -30°F to+180°F -34℃ to+82℃ Neoprene Yellow Stripe Recommended for hot lubricating oils and certain chemicals.Good oxidation resistance. Will not support combustion. ◆ As the manufacturer and innovator of grooved coupling technology, offers a variety of coupling sizes and styles for almost any piping application.

◆ All grooved couplings are made up of four parts,namely housing, gasket, bolt and nut. Housing is made of ductile iron, surface finish is orange, but also for a variety of fluid piping system to provide matching color scheme; standard gasket material is EPDM,also prepared for a variety of pipeline media rubber material. The bolt's tensile rating is class 8.8 and the nut's rating 8.0.

◆ CNG couplings provide pipe system with versatility not found in other pipe connection methods. CNG rigid and flexible couplings can be combined to allow for thermal growth within the system. Additionally, the use of three consecutive flexible couplings reduces noise and vibration and eliminates costly noise dampeners.

◆ Suitable for all variety of style 321 split flanges.

◆ Hot -dip galvanized surface

◆ Size: DN50~DN200 2"~8"

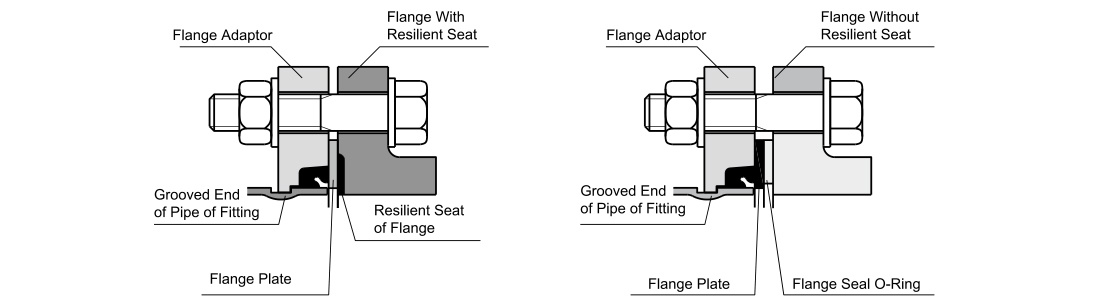

◆ Model 321 split flange assembled on a flange with a soft sealing surface, a steel plate wil be added in the middle.

◆ Model 321 split flanges are connected with the fiange without soft sealing surface, the middle of the flange should be attached metal flange gasket and rubber flange.

Related products

Product inquiry

Filling in your phone and email information will help us to contact you in a timely manner and resolve the issues you have raised as soon as possible.

Contact Information

100 meters northwest of the intersection of Hope Avenue and 283 Provincial Road, Mengcun Hui Autonomous Region, Cangzhou City, Hebei Province

Cangzhou Make pipe industry